Well..........

I just looked at it and cut out a template from cardboard and went from there

No flash tools it was all done with a hacksaw , file, bench vise and a cordless drill

Anyone would be able to make it

It would be really easy to do with a die cut press

If I had to do it again I would buy the sheet pre cut to the width and then just have to trim the top part

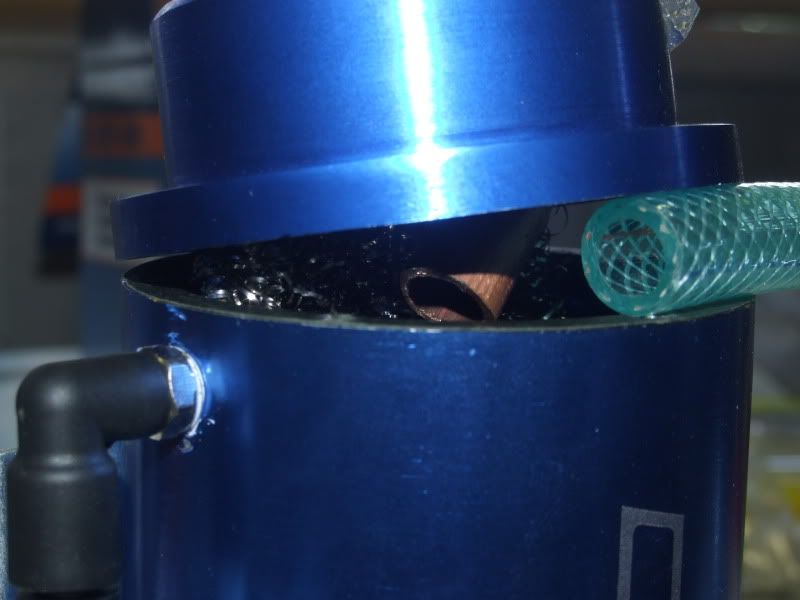

There are a heap of different ways to force the air to go through the media ather than just short cycles from input to output.I only went this way as I had everything here as far as materials go to be able to do it this way.