bods

Member

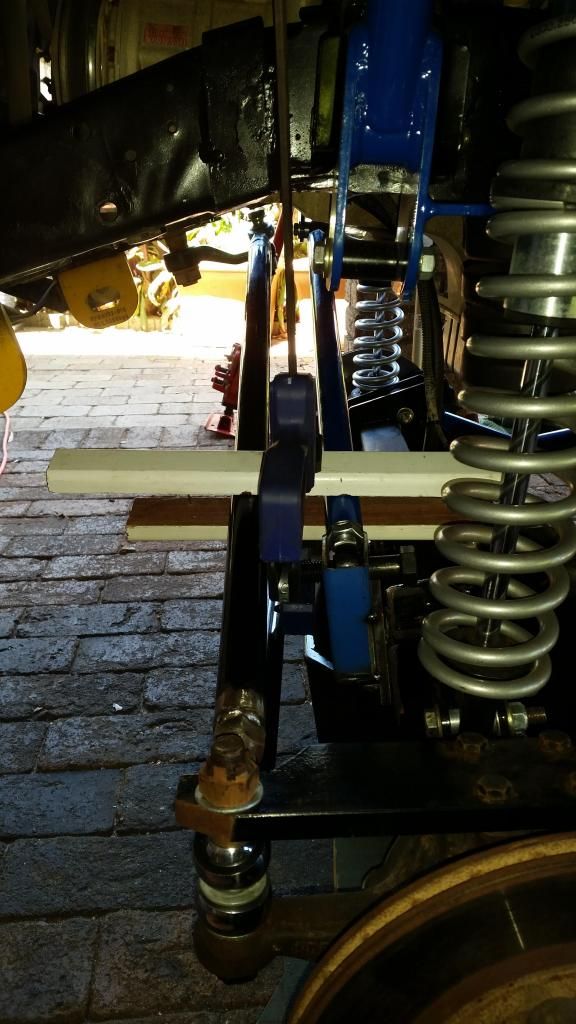

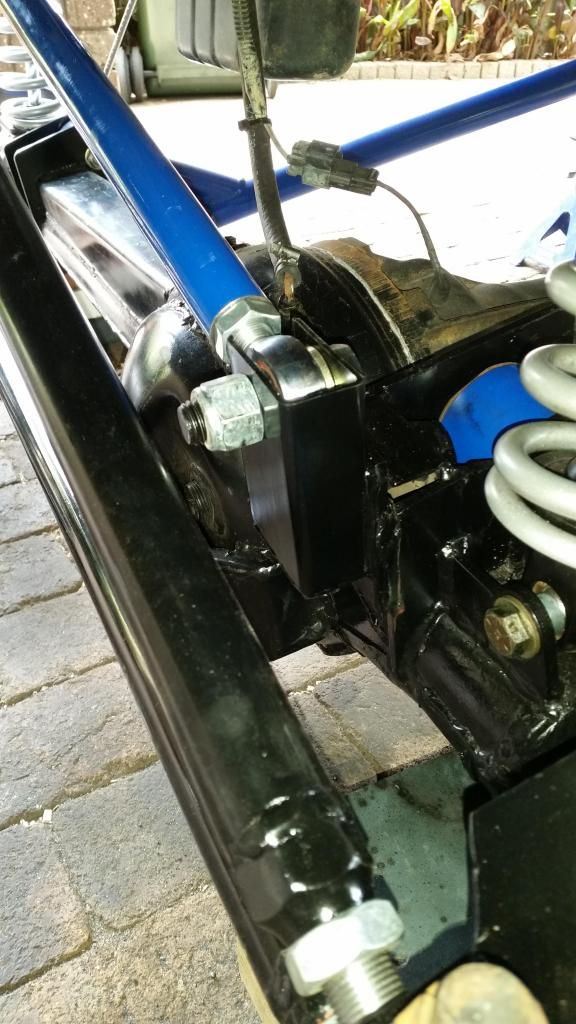

Picked up the sleeves for the rear shackles today. Also gave the old girl its first service this year. 80 series bump stops are a little to long so Im going to cut the first section off and install them tomorrow. May even get time to put the shackles in as well.

Going to get a shop to look at the brakes next week. Going to get a second opinion before I start pulling shit apart or putting bigger master cylinders in. Stay tuned for pics i the coming days

Far out, that's a bit rough, kept her waiting that long... hahahahahah

In all seriousness, its looking pretty good. Hope you get those brakes sorted soon.