Aussie Frontier

Member

I went ahead and bought a new rad from Natrad for $348 with 3 years warranty

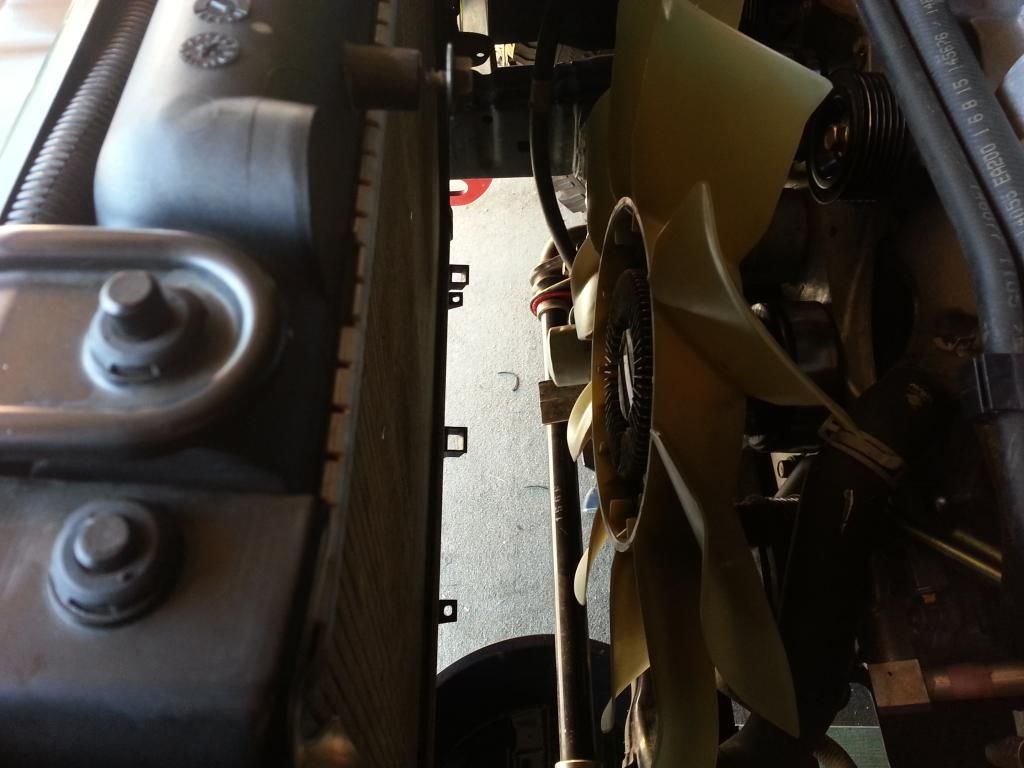

So far all I have done is pulling parts off

Remove Air Inlet tube and Engine cover

Remove Airbox ( just to get some wriggle room

Remove belly pan

Disconnect lower rad hose and drain system

remove lower section of fan shroud

Remove upper rad hose

Remove overflow hose

Remove fan belt

Remove Upper fan shroud

Remove fan and clutch

remove thermo fan

Thats what am up to so far

Have also had the hose run through as much as I can of everything including overflow bottle

I pulled out the T/Stat and checked that in boiling water and yup its working fine.

I will take pics as I go tomorrow so it will show what goes where and how its attached

bottom line

Prick of a job

So far all I have done is pulling parts off

Remove Air Inlet tube and Engine cover

Remove Airbox ( just to get some wriggle room

Remove belly pan

Disconnect lower rad hose and drain system

remove lower section of fan shroud

Remove upper rad hose

Remove overflow hose

Remove fan belt

Remove Upper fan shroud

Remove fan and clutch

remove thermo fan

Thats what am up to so far

Have also had the hose run through as much as I can of everything including overflow bottle

I pulled out the T/Stat and checked that in boiling water and yup its working fine.

I will take pics as I go tomorrow so it will show what goes where and how its attached

bottom line

Prick of a job