You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid Axle Swap!!!

- Thread starter dilmah

- Start date

Help Support Nissan Navara Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

joshy

Member

- Joined

- Oct 1, 2008

- Messages

- 2,088

- Reaction score

- 0

Coil overs are engineer able but most engineers will want at least one of the mounting eyes to be rubber.

Shame it's going to end up so high. Seeing as you are reworking the radius arm brackets I would do my best to rejig and get it lower if possible.

Shame it's going to end up so high. Seeing as you are reworking the radius arm brackets I would do my best to rejig and get it lower if possible.

That's good to know mate. I didn't think you were allowed to use a hymn joint anywhere is that true. But you made my day. I need to keep my Nav street legal and thought I may have to find another way to fit a live axle. How good are coil overs for a daily driver and travel rig. Can they handle the outback for example.

I can run softer coils so they compress more at stock height, down travel wont be affected. 8" is only an estimate at the moment. I can estimate the coil compression by dialing in the weight of the front part of the nav. The redesigned radius arm brackets will let the axle sit further forward aswell so I should have no problems clearing 37's now. Ive done most of the work in CAD today, ill export some pics and put them up when im done.

The calmini brackets were made from 1/4" thick mild steel. Im going to use 6mm wich is very close to 1/4". In my opinion this will be plenty strong enough considering stock patrol mounts are about 4mm

The calmini brackets were made from 1/4" thick mild steel. Im going to use 6mm wich is very close to 1/4". In my opinion this will be plenty strong enough considering stock patrol mounts are about 4mm

joshy

Member

- Joined

- Oct 1, 2008

- Messages

- 2,088

- Reaction score

- 0

That's good to know mate. I didn't think you were allowed to use a hymn joint anywhere is that true. But you made my day. I need to keep my Nav street legal and thought I may have to find another way to fit a live axle. How good are coil overs for a daily driver and travel rig. Can they handle the outback for example.

yeah same again as the coilover, you can have a heim joint on one end of your link but the other needs to have rubber.(this could change from engineer to engineer but is what I was told by the two that looked at mine..)

ever watched any trophy trucks or king of the hammers footage? everyone runs coilovers. like anything they need to be set up correctly but they will have no drama handling it. Infact it will be better then standard as you will have more travel.

The radius arms have rubber at the axle end. Coilovers are bolts at both ends. All my steering is Heim jointed as well as the panhard rod. If that is the case then it could be possible for engineering, just dont wanna pay the thousands for a lane change and brake test when I could spend that $$$ on putting coilovers in the rear!

The radius arms have rubber at the axle end. Coilovers are bolts at both ends. All my steering is Heim jointed as well as the panhard rod. If that is the case then it could be possible for engineering, just dont wanna pay the thousands for a lane change and brake test when I could spend that $$$ on putting coilovers in the rear!

Very true. If they only made it cheaper to get them certified more would do it and hence safer cars on our roads.

camo.b

Member

Very true. If they only made it cheaper to get them certified more would do it and hence safer cars on our roads.

I totally agree.

camo.b

Member

I saw the coolest rigs over there...seems anything goes

The test and report itself isnt expensive its the hire of a suitable venue to conduct the test that kills ya. It needs to be doen at either a raceway or on a private bitumen road where you can reach 100km/hr to do the swerve test

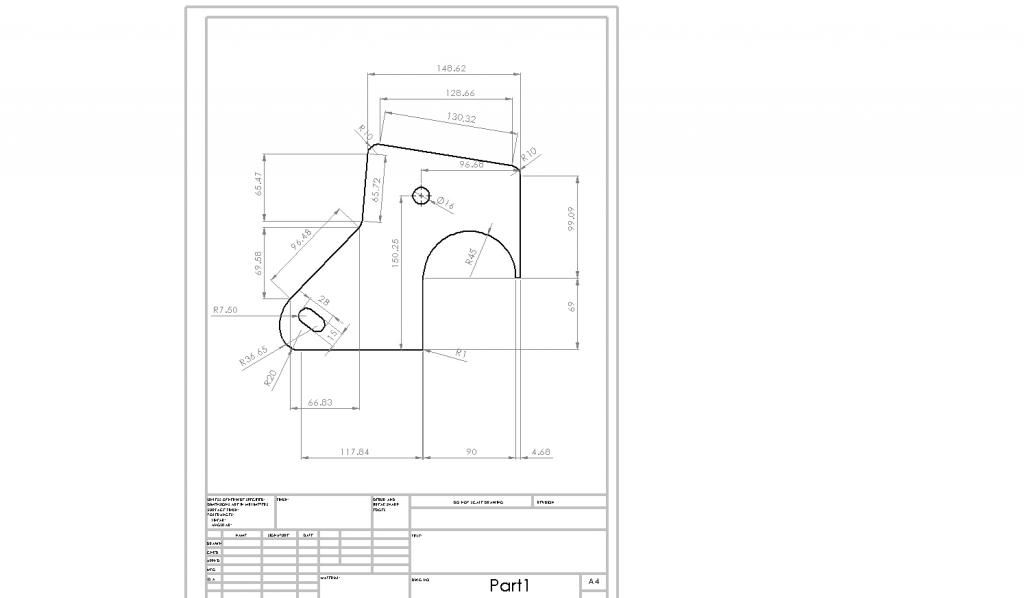

Been busy today playing arts and craft, designing my new radius arm brackets. Was really quiet simple, I used the majority of the old bracket's geometry and just added a bit where I needed the extra clearance. I also bought CV grease and the diff oil, still need to grab some copper washers for the brake lines

As you can see in the pics there is plenty of clearance now. My mate will draw them up in CAD tomoz and Ill send them off to be laser cut. Hoping to have them to me by Friday as I have a 4 day weekend. If everything goes to plan the Nav will be under its own weight by Monday.

Once the CAD drawings are done Ill post them up!

As you can see in the pics there is plenty of clearance now. My mate will draw them up in CAD tomoz and Ill send them off to be laser cut. Hoping to have them to me by Friday as I have a 4 day weekend. If everything goes to plan the Nav will be under its own weight by Monday.

Once the CAD drawings are done Ill post them up!

Brackets have been cut, Ill be picking them up tomorrow and hopefully get them tacked in place with the coilover mounts. Once this is done I can weld the final parts of the axle brace and knuckle gussets in place and give it a quick paint. Then there will be final axle assembly on Saturday and hopefully it will be under its own weight by Sunday.

After this all I have to do it the drag link and panhard rod. At this stage it will be driveable but no 4wd. Will get the shaft made after a few weeks of driving it.

After this all I have to do it the drag link and panhard rod. At this stage it will be driveable but no 4wd. Will get the shaft made after a few weeks of driving it.