You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solid Axle Swap!!!

- Thread starter dilmah

- Start date

Help Support Nissan Navara Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

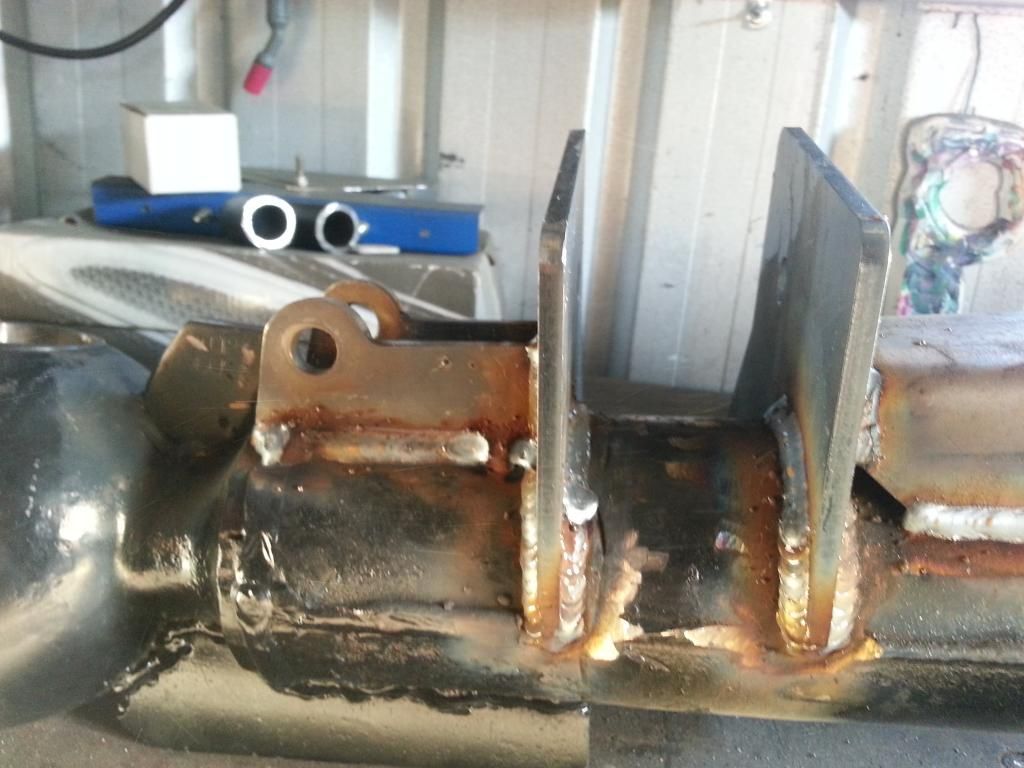

They are actually a very good fit, the weld on the axle seam is lifting it slightly, cut out of 6mm plate. Pretty happy with the quality of cut its very clean

Got the shock mounts tacked in today, had to move them a couple of times as I wasn't happy with the clearance, they are as wide as I can get them. I had to cut some of the top knuckle gusset off to fit them in.The reason for this is the radius arms need to be as wide as possible. On a GQ axle there is bugger all room on the short side of the axle before the housing starts to deform from a circular shape. I will have to either cut the housing, shock mount or radius arm bracket to get it to fit but I'm confident that I have enough room to make it all fit.

I have my mate who is a boilermaker coming around tomoz to give me a hand. Im hoping to get the radius brackets, shock mounts, sway bar mounts and diff bracing finished and fully burnt in

Also I got some 1 1/4" heims from Locktup to do something with the rear but that can wait till another day

Got the shock mounts tacked in today, had to move them a couple of times as I wasn't happy with the clearance, they are as wide as I can get them. I had to cut some of the top knuckle gusset off to fit them in.The reason for this is the radius arms need to be as wide as possible. On a GQ axle there is bugger all room on the short side of the axle before the housing starts to deform from a circular shape. I will have to either cut the housing, shock mount or radius arm bracket to get it to fit but I'm confident that I have enough room to make it all fit.

I have my mate who is a boilermaker coming around tomoz to give me a hand. Im hoping to get the radius brackets, shock mounts, sway bar mounts and diff bracing finished and fully burnt in

Also I got some 1 1/4" heims from Locktup to do something with the rear but that can wait till another day

Well made a shitload of progress yesterday, got my mate Wezza around to give me a hand with the welding. Didn't help he was hungover as fuk but a few durries and coffee sorted that! Got all of the bracelets, shock mounts, knuckle gussets and top axle brace burnt in. Wezza is a boily by trade so I know the quality of work will be better than what I can produce.

The only issue we had was the short side of the axle was very tight for space as most of you will be aware a GQ diff has a very wide pumpkin offset meaning a very short axle on the passenger's side. We had to cut out a lot of the radius arm bracket, grind down the housing and cut 15mm off the shock mounts. to get everything to fit. This took the best part of 2 hrs and Wezza was only here for 4!

Time for some pics

The only issue we had was the short side of the axle was very tight for space as most of you will be aware a GQ diff has a very wide pumpkin offset meaning a very short axle on the passenger's side. We had to cut out a lot of the radius arm bracket, grind down the housing and cut 15mm off the shock mounts. to get everything to fit. This took the best part of 2 hrs and Wezza was only here for 4!

Time for some pics

Did some more work on the truck today. Started off by cutting the caster adjusters off the original brackets and welded them onto the new radius arm plates. I then cleaned the entire housing with brake cleaner to remove the weld splatter, slag and any dirty and oil build up. I then gave it a coat of primer where ever there was exposed steel and got 1 coat of rattle can black in before it got too dark.

And finally the res' are out of the way, another little job that took 10 mins out of the way!

I had enough for the day so I retreated inside to drink beer.

No the next part is going to be a little tricky, I have 2 options;

1) Assemble axle on the horses, put tires on and roll under Nav. It shouldn't be too hard to bolt the radius arms up but it will be difficult to compress the shocks to get them in. While it will be easier to assemble the axle it will be harder to put it in place. Remembering I don't have a engine hoist only a trolley jack and 2 hi lifts

2) Put axle under Nav first and bolt up shocks and radius arms. Then assemble axle while it is under nav and sitting on axle stands. Jack up each side to put the tires on then sit it on its own weight. While it will be easier to bolt the axle up it will be harder to assemble as I will essentially be sitting on the ground.

I had enough for the day so I retreated inside to drink beer.

No the next part is going to be a little tricky, I have 2 options;

1) Assemble axle on the horses, put tires on and roll under Nav. It shouldn't be too hard to bolt the radius arms up but it will be difficult to compress the shocks to get them in. While it will be easier to assemble the axle it will be harder to put it in place. Remembering I don't have a engine hoist only a trolley jack and 2 hi lifts

2) Put axle under Nav first and bolt up shocks and radius arms. Then assemble axle while it is under nav and sitting on axle stands. Jack up each side to put the tires on then sit it on its own weight. While it will be easier to bolt the axle up it will be harder to assemble as I will essentially be sitting on the ground.

Brett 76

Member

Looking bloody awesome mate, will be a weapon once she's finished and eating the tracks up

Joshp82

Member

Can you put it together on the horses. Wheel it close take the wheels off and then jack it back up to put wheel on? Make a small skid trolly to sit it on to get it under the car

Ive decided I'm going to assemble the axle under the Nav. Compressing coil overs got put int he too hard category, it will just be easier to use 2 trolley jacks to lift the axle up into place. I spent today painting it so tomoz will be assembly. I go back to arvo shift tomoz so progress will be slow from now on.

Joshp82

Member

Any updates?

Well made some progress over the last 2 days, axle is bolted to the shocks and radius arms. Third member is bolted in, one cv and both hubs are bolted on. I need to move the nav forward a little to put the long cv in. The brick pillar is in the way! Pics will explain it a little better.

Gotta work on the steering as Tom suggested, fab a panhard rod mount and a drag link. Need to get some more offset 16x8's as the current ones are rubbing on the brake calipers

Gotta work on the steering as Tom suggested, fab a panhard rod mount and a drag link. Need to get some more offset 16x8's as the current ones are rubbing on the brake calipers

bods

Member

Looking very good. Any plans for the rear end? Be interesting to see the stock diff converted to a 4 link with coil overs.....