You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear 4 Link

- Thread starter dilmah

- Start date

Help Support Nissan Navara Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

DeanosD22

Member

Very nice mate another box ticked! Can't wait to see this thing in action

I havnt done much on the car in the last 2 weeks. Been busy with other crap. I will have an update (and pics) by the weekend. Hoping to have most of the shock towers burnt in

I put in a GU steering box and pulled out the ABS, old fuel lines and old brake lines.

I put in a GU steering box and pulled out the ABS, old fuel lines and old brake lines.

I had to mount the tank backwards (fuel sender is normally on drivers side) as It gave me better clearance for the bypasses

As you can see in the last photo the tank sits up nice and high. The rear cross member which will tie the back of the chassis together is a piece of 70 x 50 x 6mm RHS. With the correct bracing I should have no problems recovering off the rear of the chassis should I choose to do a CCDA event. I have tapped the 3 M8 x 1.25 bolt holes directly into the cross member for the fuel tank.

As you can see in the last photo the tank sits up nice and high. The rear cross member which will tie the back of the chassis together is a piece of 70 x 50 x 6mm RHS. With the correct bracing I should have no problems recovering off the rear of the chassis should I choose to do a CCDA event. I have tapped the 3 M8 x 1.25 bolt holes directly into the cross member for the fuel tank.

Leprechaun

Member

- Joined

- Apr 3, 2009

- Messages

- 2,792

- Reaction score

- 2

Just some advice as I've done a similar thing before. Next time I would recommend you bolt the cross members rather than welding. The chassis flex could result in the RHS tube splitting at the heat effected zone next to the welds.

It is embarrassing when your fuel tank in or in my case a LPG cylinder falls out on the tracks.

It is embarrassing when your fuel tank in or in my case a LPG cylinder falls out on the tracks.

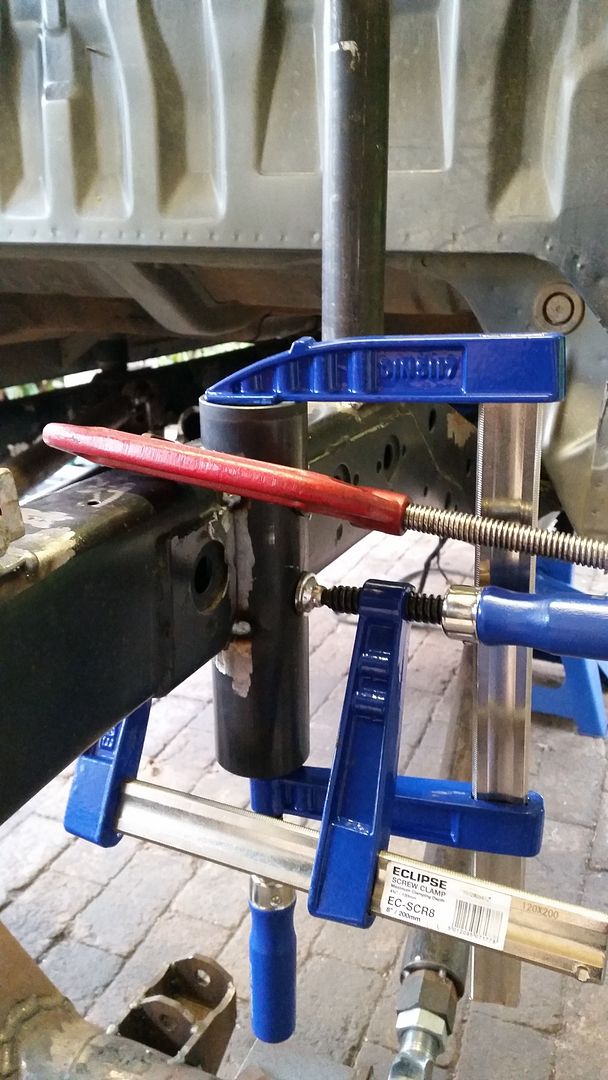

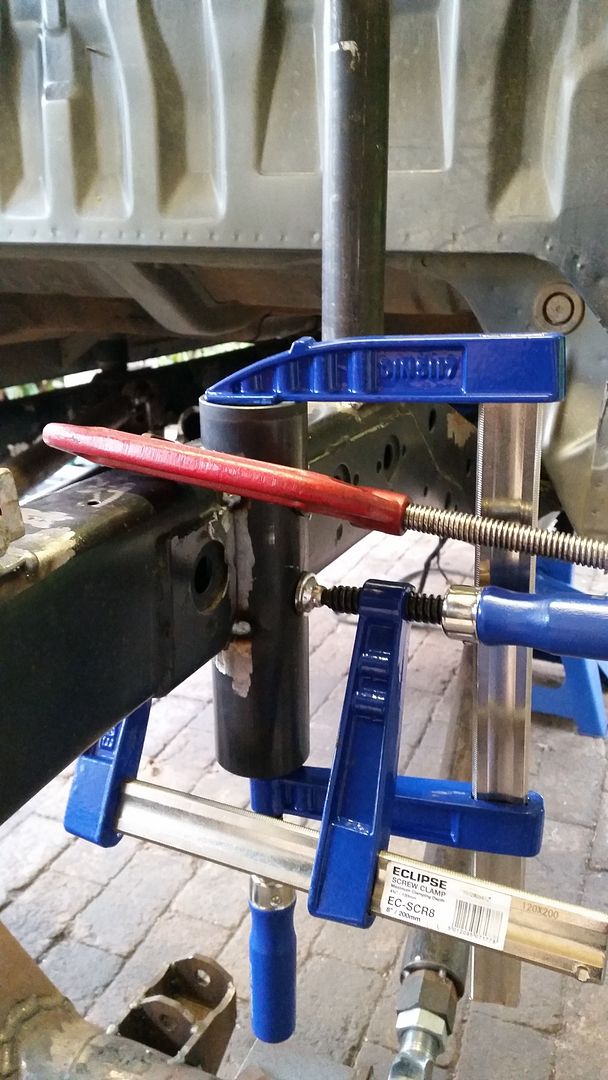

Been plodding along with the build this weekend. Notched the chassis on Friday for the bump cans, went in about 1/2 way. Tacked them in Saturday. There is a 50mm solid bar inside to stop them shrinking smaller than 50mm. This is a common problem when welding bump cans. I left it in there for a good 30 mins while the metal cooled.

I drilled a 19mm hole in the bottom of the GQ tank and put a 1/2 Bsp fitting in to act as a drain plug

I put both sets of shocks in and flexed it up to see how everything was looking. The only problem I found was that the lower coilover brackets were too small for the massive eyes on the 3.0 fox shocks. I will have to design some shock tabs in CAD and get them laser cut this week

I put both sets of shocks in and flexed it up to see how everything was looking. The only problem I found was that the lower coilover brackets were too small for the massive eyes on the 3.0 fox shocks. I will have to design some shock tabs in CAD and get them laser cut this week

Spent some long hours in the shed on Friday and Saturday. Feel like the truck is finally coming together now and I can see it being finished. I lost interest there for a while as there was soo much work to do.

Here is an update:

Picked up the crown wheel and pinion and brake disks from getting heat and cryo treated on Tuesday

Brake lines are done for the upper link arms

I also welded on a S/Steel bracket for the braided lines to attach to but forgot to take photos

Here is an update:

Picked up the crown wheel and pinion and brake disks from getting heat and cryo treated on Tuesday

Brake lines are done for the upper link arms

I also welded on a S/Steel bracket for the braided lines to attach to but forgot to take photos

Similar threads

- Replies

- 11

- Views

- 3K