With the guard removed and snorkel removed we revved the engine again and the hoses collapsed. Now we removed the inner snorkel tube and revved the engine again. Still the hoses collapsed. Mat noticed the air cleaner canister looked odd were it fitted into the side of the guard, connecting into the snorkel housing. Walla, he discovered the problem. Someone had fitted a flexible tubing inside the snorkel housing which then connected into the air cleaner canister. What was happening under load (revving) she was breathing, however, as soon as you stopped the revs, the vacuum sucked the flexible tubing into the air-filter causing an obstruction resulting in the hoses collapsing, which then causes only fuel to the motor and no air, resulting in a stalling effect.

On closer investigation, i noticed faded writing on the passenger side guard. What i surmised was that the Patrol had been in an accident and suffered damaged to the passenger side guard, the repairer replaced the snorkel and guard, however, they did not replace the air cleaner canister which was damaged. They simple cut off the damaged outlet section that fitted into the guard and simple fitted 60mm flexible tubing from the snorkel inlet housing into the air filter canister and used a shit load of silastic to seal the joint. ( A couple of days latter, I rang the previous owner whom confirmed that the Patrol had been hit on the passenger side and had the snorkel and guard had been replaced by a local panel beater in Keillor, Victoria)

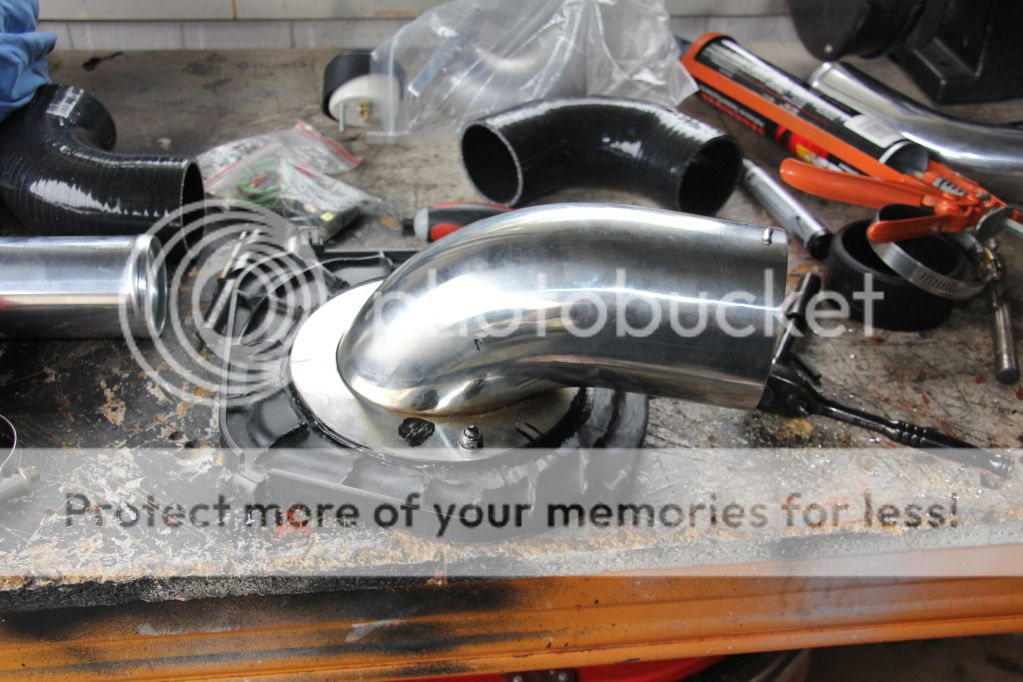

nissannewby and I went to the local hardware store picked up a 90mm plumbing fitting and some 90mm pipe, viola, problem fixed !

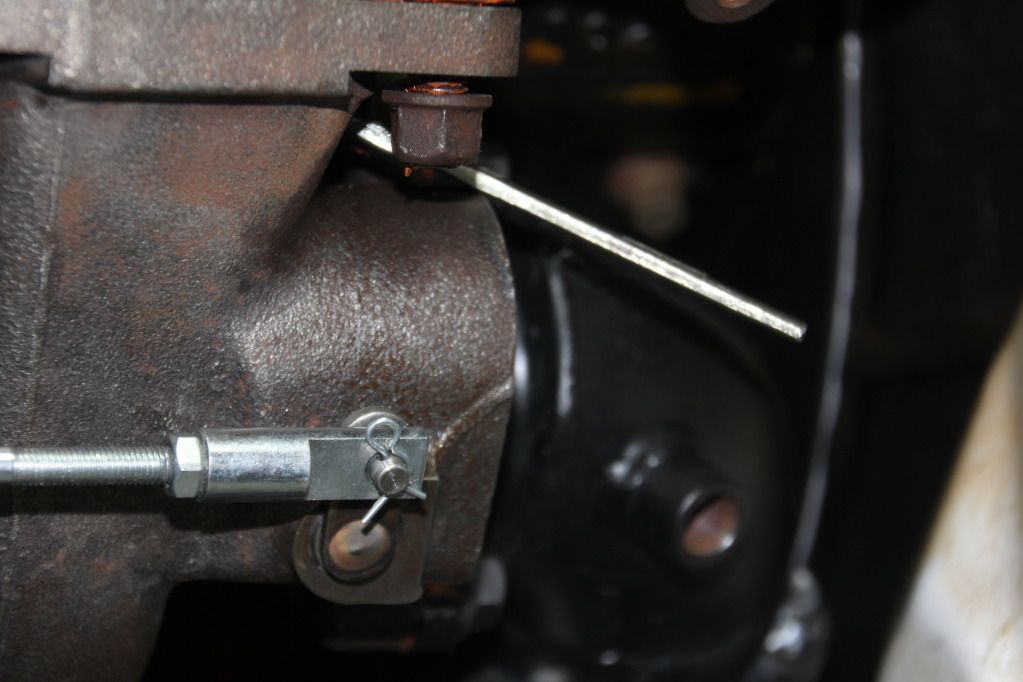

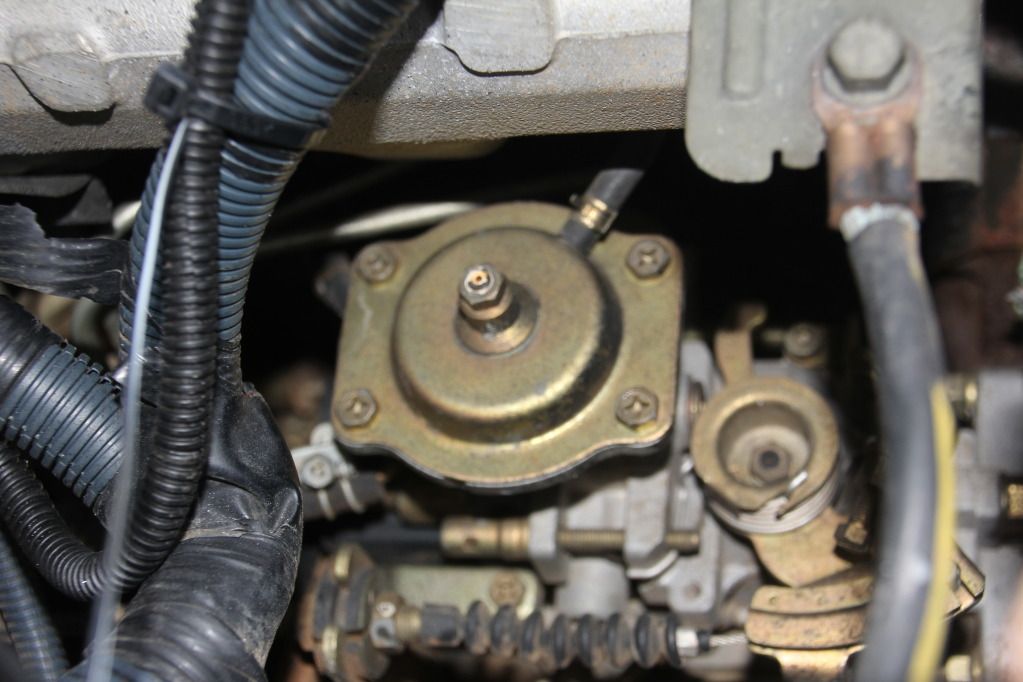

nissannewby contacted Matt Craig from United Fuel Injections, advised him of the situation, he laughed, has he advised us that he has seen some horrid modifications that have come into his workshop over the years. Matt Craig then guided young nissannewby on how to adjust the injector pump.

Firstly, undo the 4 x 10mm bolts that hold the diaphragm cover. Gentle remove the cover, mark the diaphragm location with a sharp scribe/nail. Remove the compensator diaphragm and place on a clean rag and cover it.

more to follow over!